You might have some questions about this step. Like, “Why is this step about designs? I thought you made the designs in the Proposal step.”

You’re partly right — we did make designs as part of creating the proposal, but that’s an example of concept design. The results aren’t quite the same as the technical designs created in this step.

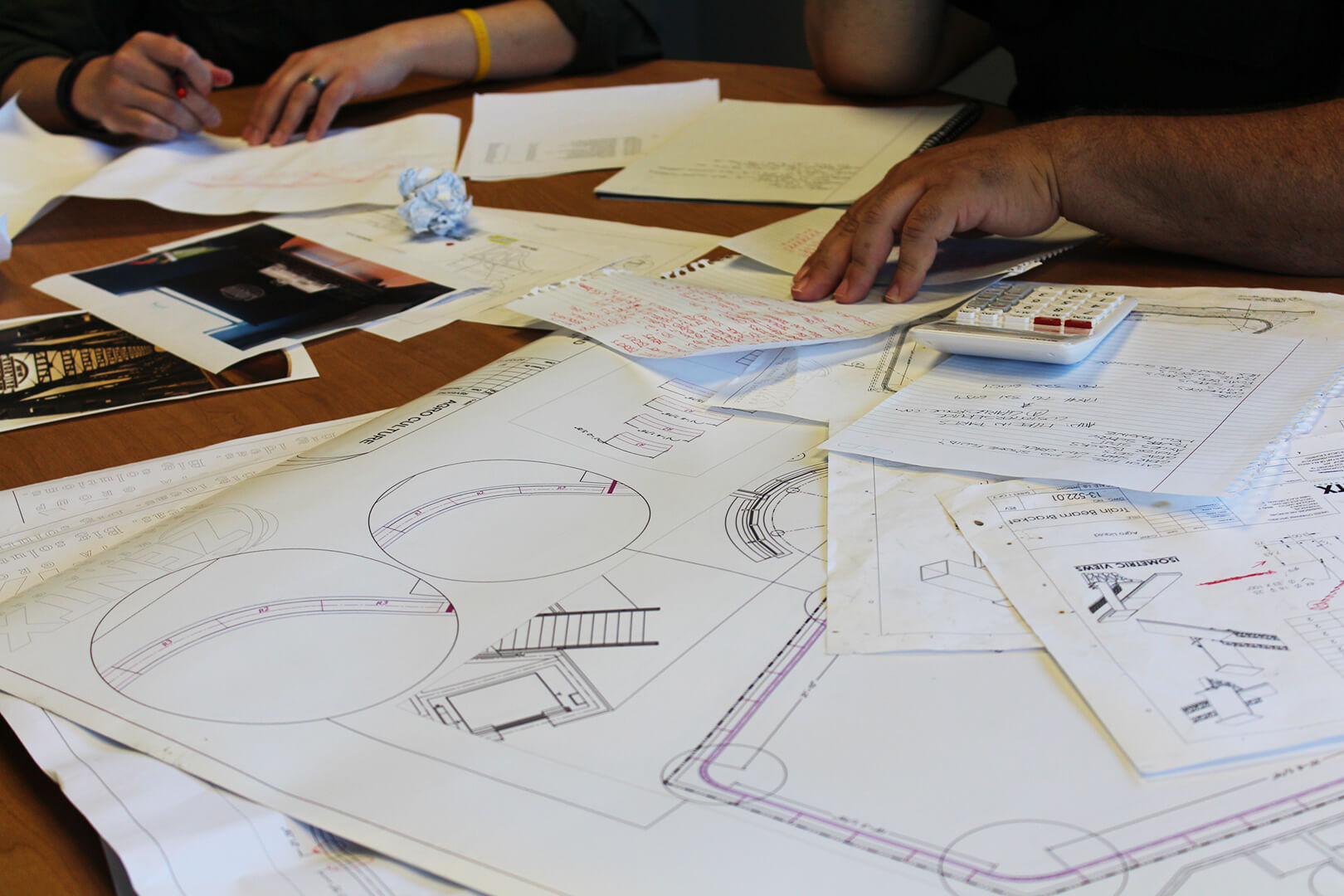

Back to the Drawing Board

Why is there a difference? Well, when we presented our proposal to Fullerton Tool, our designs just needed to show them what we were thinking of. There wasn’t a point in making technical, detailed designs, since Fullerton might decide they didn’t want a particular element after all, or they might have wanted to make some changes to an element.

But we can’t build our creative projects without a blueprint, and concept drawings just aren’t blueprints. After Fullerton approved the proposal, we knew what we were building. And once we finished the timeline, we knew how long we had to build it. At this point, we just needed the guidelines.

So we went back to the drawing board (or the drawing software, more accurately) and our fabrication leader worked with our designers to figure out the engineering. Sometimes that involves making 3D renderings, and other times it’s a question of traditional 2D drawings. Either way, it takes your ideas one step closer to becoming a real-life solution.

Testing, Testing

Then there’s the prototyping stage. This doesn’t happen with every project (as it turns out, it didn’t happen with Fullerton’s). But with some projects, especially ones that we’re designing completely from scratch, we want to do a test run just to make sure things work the way we think they will.

To jump to another job for a second, we used prototypes to help create some product displays for EXCEPTIONAL Metals. Since we came up with the structure of the displays ourselves, we decided to test them before cutting materials for the real ones. That way, if the design needed a re-do, we hadn’t used any materials on something that wouldn’t work. Fortunately, the full-scale cardboard prototype confirmed that our design worked (and gave our craftsmen some practice putting the pieces together).

We’ve gone all the way from an initial discovery meeting to creating a plan and a timeline, and now we’re all set up to jump into the work itself. Which means that the next step in our process is finally Fabrication — the actual building part. And Fullerton’s project called for a lot of different kinds of fabrication: CNC work, metal fabrication, and more. Check back next time to hear the details!